Resistance Temperature Detectors (RTDs)

Resistance temperature detectors, or RTDs, are the top choice for applications requiring high accuracy in temperature measurements. The Pt100 RTD’s resistance increases linearly as the temperature increases making these the ideal choice for many applications and where temperature measurement is crucial. Resistance temperature detector sensors are often preferred over other temperature-sensing devices because of their accuracy, stability, repeatability, and sensitivity.

Eustis/Pyrocom manufactures a wide variety of RTDs to meet many temperature-sensitive applications. Contact us for more information regarding our RTDs or request a quote for more specific needs and pricing options.

Industrial Resistance Temperature Detector Sensor Options

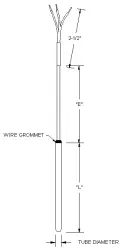

Eustis/Pyrocom provides many options for resistance temperature detector sensors to meet a variety of industrial applications. Our RTDs display temperature in °F or °C and contain a platinum coil wire wound deposited onto a ceramic substrate. Many of our RTDs are built for higher temperatures with MgO sheathed resistance (up to 900° F or 480° C) or low temperatures (-50° to 260° C) depending on your applications. Several are offered in single or dual elements to offer more versatility in applications. Others contain a thin film that is commonly used when faster response time is required and minimal size is necessary. Through the DIN establishments of IEC-751 Class B + .30°C and Class A + .15°C @ 0°C, elements in this section are 100Ω .00385 curve. We manufacture the following Pt100 RTDs styles:- RE Style Tube and Wire

- RL Style Metal Transition

- RH Style Connection Head

- RF Style Flexible Armor

- RG Style High Temperature

- RA Style Adjustable Length

- RR Style Industrial Remote

- RV Style Room Air Sensors

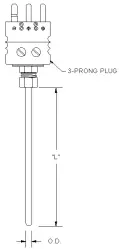

- RC Style Plug Termination

- RM Style Molded Transition

- Industrial Resistance Temperature Devices (RTDs)

Benefits of Pt100 RTDs

Resistance temperature detector sensors with their specific design of platinum wire around ceramic core offer many benefits for temperature resistance. These are built to several tolerances and curves to handle a wide range of temperature differences and also give acute accuracy to the temperature readings. RTDs are stable over time to offer consistent readings and can maintain their performance for many years showing repeatability. The resistance temperature detector sensors are easy to use and give a linear output making these ideal for control systems.Applications of Resistance Temperature Detector Sensors

Pt100 RTDs are best used for many industrial applications where temperature measurement is crucial. These are best used in industrial fields of processing and industries where temperature accuracy is of the utmost importance. Industries that RTDs are commonly used in include:- Chemical and petrochemical processing

- Power generation

- Food and beverage processing

- Automotive industries

- Aerospace

- Manufacturing

- Electronics manufacturing

Difference Between Resistance Temperature Detectors and Thermocouples

While many devices are used for similar purposes, there are important differences between thermocouples and RTDs. Depending on your application, one may be better used than the other. To determine which to choose, analyze the application and see what is most important. The key differences between thermocouples and RTDs include:- Mode of operation: Thermocouples produce voltage in response to temperature differences while RTDs utilize resistance change

- RTDs offer higher accuracy, especially at lower temperatures typically within levels of 0.1°C

- Thermocouples offer a wider range of temperature operations usually -200° to 2,000°C compared to -200° to 600°C for RTDs

- Thermocouples offer a faster response time between 0.1 and 10s compared to RTD sensors

- RTDs can self-heat compared to thermocouples

- RTDs provide a linear graph between resistance and temperature whereas thermocouples do not

Eustis/Pyrocom is Your Manufacture for Resistance Temperature Detector Sensors

With over 60 years in the industry, Eustis/Pyrocom produces high-quality thermocouples, resistance temperature detectors, thermowell and protection tubes, connection heads, and many thermocouple connectors and fittings. Our ISO 17025 certification and thorough testing processes ensure top-quality thermocouples and RTDs that meet industry requirements. View our selection of resistance temperature detectors and other products for our top service for all your thermocouple and Pt100 RTD needs!Contact Us for More Information about Pt100 RTDs

Contact us for any questions about our RTDs or other temperature monitoring equipment manufactured by Eustis/Pyrocom. In addition, request a quote for more specific needs and pricing information. Eustis/Pyrocom is your trusted source of resistance temperature detector sensors.